What are OEM and ODM?

OEM and ODM are two familiar terms in the manufacturing industry. In this article, VCU shares with readers a more detailed explanation of these two terms, helping you gain an overview and determine whether you are using an OEM or ODM product.

What is OEM?

OEM stands for Original Equipment Manufacturer, which refers to a production cooperation model. OEM is commonly used to describe companies or factories that manufacture products based on pre-designed specifications provided by another business. Simply put, the OEM unit manufactures products “on behalf of” another company. These products are then sold under the brand name of the ordering business.

OEM allows businesses to save on production costs and focus on brand development.

Example: An example of the OEM model is the partnership between VCU and coffee chain X. In this case, X is the client, responsible for packaging design, coffee recipe development, and product distribution. VCU, on the other hand, acts as the OEM company, producing roasted/ground coffee from green beans and packaging the products under X’s branding.

Learn more about OEM services at VCU: OEM Coffee and Private Label

What is ODM?

ODM stands for Original Design Manufacturing. This is a model in which the manufacturer both designs and produces the product, then sells it to another brand. Unlike OEM, ODM is responsible for both the design and production.

If a business faces challenges or limitations in product design, ODM companies can help turn ideas into actual designs. ODM provides an opportunity for businesses to bring products to market without investing heavily in design and manufacturing.

Example: Company A places an ODM order with company B. A sends its idea to B, and B is responsible for designing the packaging and branding based on A’s concept. Once the design is completed, mass production is carried out at an optimized cost.

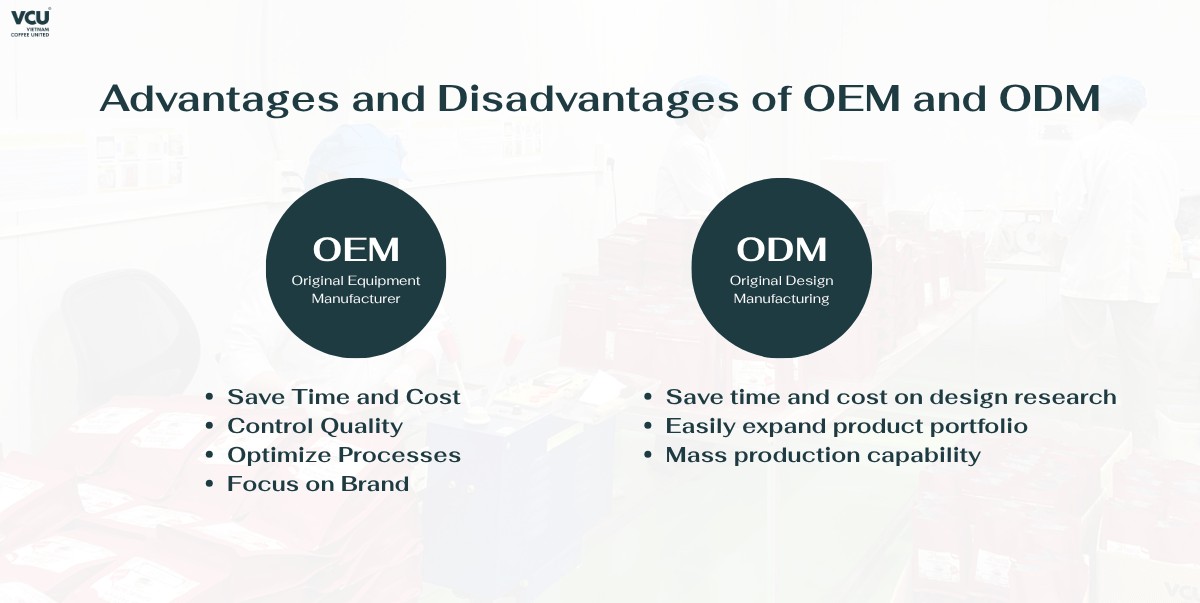

Advantages and Disadvantages of OEM and ODM

Although OEM and ODM share some similarities, many people still confuse the two. Below are some pros and cons of both models:

OEM – Pros and Cons

Pros:

The biggest advantage of OEM is reducing initial investment costs. Businesses can access modern technology and manufacturing processes without having to invest in infrastructure, equipment, and staff training.

In addition, working with a reputable OEM partner allows businesses to easily control product quality, optimize the supply chain, and customize flexibly during business operations.

Cons:

One drawback of the OEM model is the dependence on the manufacturer and the potential risks related to data and design confidentiality.

ODM – Pros and Cons

Pros:

ODM provides a comprehensive solution from design to production, with customization according to client needs. It helps businesses save time and costs on research, design, and manufacturing. Additionally, it’s easier to expand the product portfolio as ODM partners are capable of mass production.

Cons:

Since ODM involves design and mass production, the cost is usually higher than OEM. Also, product development time may be longer.

Should You Choose OEM or ODM?

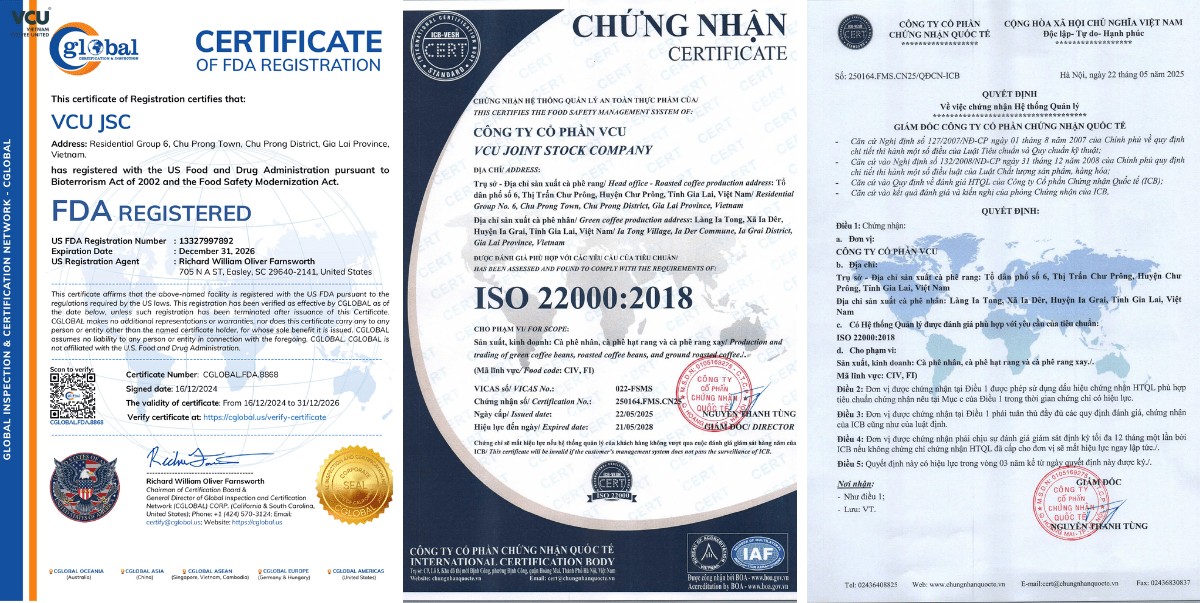

Whether you choose OEM or ODM, assessing quality standards and evaluating the manufacturer is crucial. In the F&B sector, particularly in coffee products, manufacturers must strictly follow procedures to ensure food safety and hygiene standards. This contributes to building trust with consumers.

For businesses that want to reduce costs, focus on branding, and avoid manufacturing investment, the OEM model is a suitable choice.

For those who want to save time and design costs, but still wish to have unique, customized products, the ODM model is ideal.

OEM Service at VCU

Finding a reputable OEM partner and understanding the process will help businesses optimize costs, improve product quality, and better position their brand.

With 4 years of experience in coffee processing and manufacturing, VCU is currently one of the largest roasting facilities in the Northern Central Highlands region. VCU not only provides pure roasted coffee but also offers OEM coffee services—contract manufacturing under the customer’s brand.

Save Time and Costs

No need to invest in roasting/grinding equipment or master complicated roasting techniques. The cost of high-end roasting equipment is substantial. OEM services also eliminate operational and labor costs associated with in-house roasting.

Consistent Quality

VCU’s team of skilled roasters has years of experience and constantly upgrades their knowledge and skills. VCU operates two industrial roasting machines using modern Hot-air roasting technology, ensuring consistency in every roast. This consistency is essential for maintaining customer satisfaction and brand reputation.

Customizable to Your Needs

VCU’s dedicated R&D and roasting team is always ready to help you adjust roast levels and flavor profiles to suit your brand and target customer preferences.

Build a Unique Brand Identity

VCU acts as a solid back-end partner. Choosing VCU’s OEM service allows you to reduce costs while focusing on brand development, marketing, and sales.

We hope this article has helped you better understand the OEM and ODM models. If you’re interested in OEM services, don’t hesitate to contact the VCU team for support!

Contact Information

VCU Joint Stock Company (VCU JSC)

Address:

– Roasting Facility: Residential Group 6, Chu Prong Town, Chu Prong District, Gia Lai Province

– Green Bean Facility: Ia Der Commune, Ia Grai District, Gia Lai Province

– Fanpage: VCU – Vietnam Coffee United

– Email: info@vietnamcoffeeunited.com