Basic Issues in the Coffee Roasting Process

Coffee roasting process uses heat to transform green coffee beans into roasted beans. Roasters have to go through trials, mistakes, and taste numerous coffee batches to develop a system of theories and experience. Let’s take a look at the basic issues that a roaster needs to understand!

Changes During Coffee Roasting

In simple terms, roasting is the process of applying heat to turn green coffee beans into roasted coffee that we can grind and brew. However, the coffee roasting process involves various reactions, such as the Maillard reaction, caramelization, and crack sounds (First crack, Second crack).

You can read more details in this article: Chemical Changes in Coffee Roasting

Before roasting, coffee beans are green with a smell similar to beans or grass, or with characteristics of their variety. The aromas and flavors only start to develop when heat is applied for roasting. The entire creation of flavor is controlled by two mechanisms: one part scientific and physico-chemical reactions, and the other part art and inspiration.

Chemical Changes During Coffee Roasting Include:

- Color changes from green to yellow, brown, and then black.

- The beans nearly double in size, lose mass, and become more porous and brittle.

- Around 800 flavor compounds are formed, though if roasted too long, these compounds significantly decrease.

- When the beans release steam and gases, cracking sounds may be heard.

In the next section, we’ll explore the stages of the roasting process.

Stages of Coffee Roasting

To understand roasting principles and the differences between roasting techniques, roasters must have a general understanding of the chemical and physical changes occurring during the process. This process can be divided into distinct stages, which helps roasters control production and achieve consistent quality in each roast batch.

The coffee roasting process is divided into three basic stages:

1. Drying Phase

Green coffee beans after processing have a moisture content of 10–12%. To develop the coffee’s flavors, the beans need to be dried first. Simply put, the coffee cannot change from green to brown if water is still present inside the beans.

The drying phase removes excess moisture. The coffee beans absorb hot air from the roaster’s burner, causing water to evaporate after a certain period. Drying changes some of the bean’s characteristics: volume increases, internal pressure rises, mass and density decrease, and the color changes from green to yellow. When the beans turn deep yellow, it marks the end of the drying phase.

This phase typically lasts 4–8 minutes, accounting for 30–50% of the total roasting time. Shorter or longer times can risk burning the coffee or not achieving the desired flavor.

2. The Middle Stage

Though not a specific stage, we include the middle phase after drying, as the green coffee turns yellow or light brown. Some literature refers to this as the browning phase.

At this stage, the natural sugars in the beans undergo chemical reactions, along with steam release, causing the beans to expand and emit a distinctive aroma. Color and aroma changes mainly result from the Maillard reaction, occurring at around 121–149°C (250–300°F).

At about 171°C (340°F), caramelization begins, reducing the natural sugars. Caramelization creates changes in color and adds fruity, toasted, or nutty flavors. Both reactions decrease sweetness and increase bitterness in the beans. A significant amount of smoke is also released, so roasters need to ensure proper airflow to exhaust the smoke and debris.

3. Development Time

This stage starts from the first crack to the point when the beans are released from the roaster.

Due to the two previous stages, the beans are dried and have developed a full range of flavor and aroma. This final roasting stage will determine whether to retain or reduce acidity, aroma, and body. This is also when the roaster decides the profile of the roast.

The development stage typically accounts for 18–25% of the total roast time, depending on the desired flavor and roast level:

- 18%: Highest acidity level.

- 20%: Balanced acidity and body, optimal for aroma.

- 22%: Highest body level.

- Over 22%: Medium or dark roast, suitable for drip coffee or espresso brewing.

Roast Levels

The roast level is also a crucial aspect of the process. To showcase the original flavors of a coffee variety, altitude, processing method, and climate, a light roast is often used. The darker the roast, the more the initial flavor diminishes, replaced by flavors produced by heat and chemical and physical reactions. Therefore, the darker the roast, the harder it is to distinguish the origin of the coffee.

Each brand has different roast levels to serve their business needs and customer base. At VCU, we roast according to customer profiles with light, medium, medium-dark, and dark roast levels.

Agtron Scale

Roasting coffee is a process of applying heat that turns green coffee beans into roasted coffee. At the light roast level, coffee expresses many original flavors and characteristics. The darker the roast, the more the initial flavors fade. At this point, measuring the coffee color helps roasters assess the roast level and standardize the production process.

The most accurate method is through the Agtron scale. In principle, the Agtron machine uses ultraviolet light to shine on the coffee beans, and sensors detect the reflection levels to analyze the color.

An Agtron machine has two scales: M-Basic (Commercial Scale) and Gourmet Scale (similar to a ruler with both centimeters and inches). Each scale is developed to meet the needs of different roasters at varying scales. Below is the Agtron Gourmet scale roast level defined by the SCA:

- Light: > 70

- Medium Light: 61–70

- Medium: 51–60

- Medium Dark: 41–50

- Dark: 35–40

- Very Dark: 25–34

Besides Agtron, roasters also combine using temperature, smell, color, and sound to monitor the coffee roasting process.

Crack Sounds

As mentioned above, Agtron is not the only way to monitor bean changes during roasting. We introduce four basic roast levels as follows:

1. Light Roast

This roast level is achieved after the first crack. It retains the coffee’s inherent qualities. Light roast coffee has fruity flavors, higher acidity, sweetness, and less bitterness. It’s popular in Northern Europe and for cupping.

2. Medium Roast

The coffee is taken out between the first and second cracks (city roast). At this point, the coffee has a medium brown color, dry surface, and no oil yet present.

Medium roast has a balanced flavor profile, with pleasant acidity, sweetness, and bitterness. It’s popular in the U.S. and suitable for various brewing methods, particularly espresso.

3. Medium-Dark Roast

This roast level is achieved after the second crack. The coffee has a dark brown color with a slight sheen and high uniformity.

Medium-dark roast has a dominant bitterness, rich flavor, lower acidity, and reduced sweetness. It’s suitable for drip, espresso, or moka pot brewing.

4. Dark Roast

After 30–60 seconds of the second crack, the coffee is taken out. At this level, the coffee has a dark color and a shiny, oily surface. The darker the roast, the more caffeine breaks down.

Dark roast coffee has a strong, smoky flavor, high bitterness, and no original sweetness or acidity, leaving a bold aftertaste. It suits Robusta beans and the strong preferences of Vietnamese consumers: black, bold, and bitter.

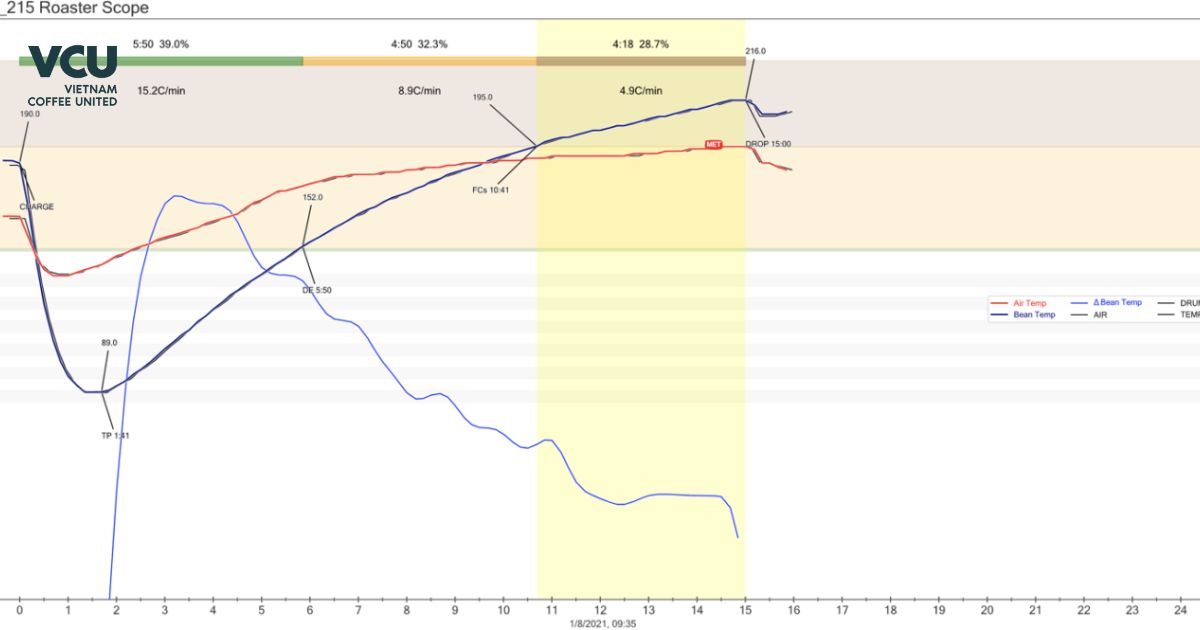

Roasting Profile

Roasting coffee is a process that requires research, study, experience, and practice by roasters. Repeating the same steps—setting up the roaster, adjusting temperature during roasting, and fine-tuning the formula—is something many are interested in.

Two extremely important factors in roasting are temperature and time. Even small changes in either can lead to different coffee flavors.

The roasting profile is understood as a “process record” for roasters, documenting the adjustments made during roasting and how they affected the bean flavor. It also records basic parameters like charge temperature, first crack, second crack time, etc.

Roasting profiles provide the following benefits:

- Storing profiles helps roasters compare different profiles to fully exploit coffee flavors.

- Helps roasters understand the physical changes in the beans and how flavor evolves.

- Helps roasters understand their roaster’s operation.

- Helps roasters maintain consistent quality in future batches when customers reorder.

Roasting coffee correctly and with the right technique is a challenge, requiring a combination of specialized knowledge, passion, dedication, experience, and even failures.

Through this article on the basic issues in coffee roasting process, VCU hopes to provide readers with useful information!

Contact Information

VCU Joint Stock Company (VCU JSC)

Address:

– Roasting Facility: Residential Group 6, Chu Prong Town, Chu Prong District, Gia Lai Province

– Green Bean Facility: Ia Der Commune, Ia Grai District, Gia Lai Province

– Hotline: +84 941 203 879

– Fanpage: VCU – Vietnam Coffee United

– Email: info@vietnamcoffeeunited.com

Source: Primecoffea.com