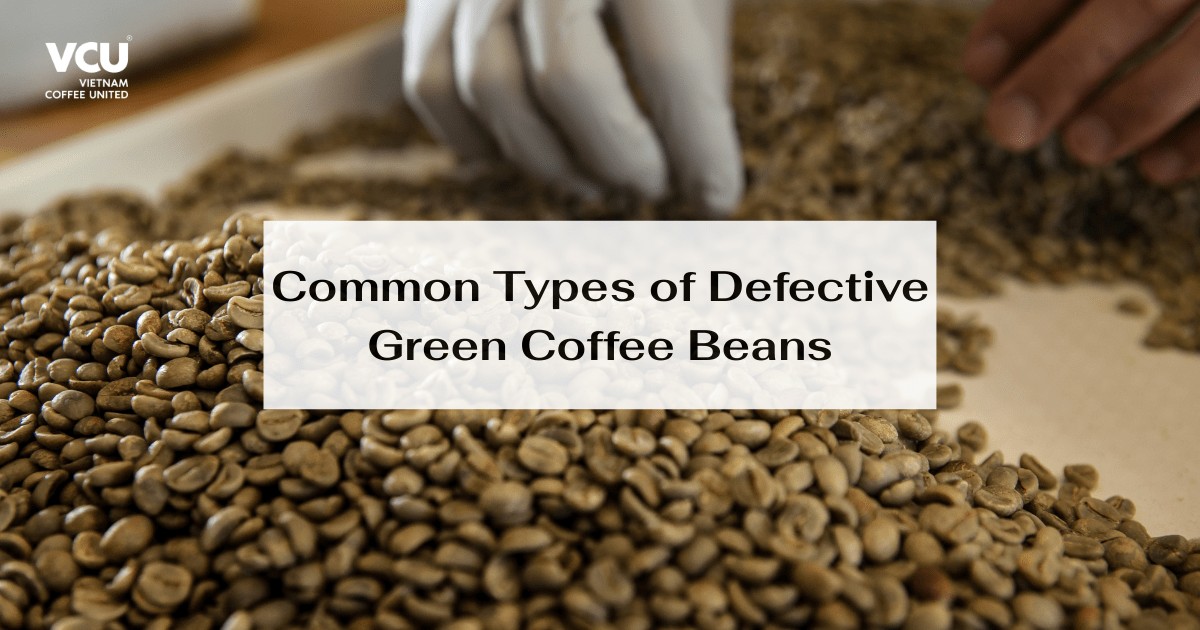

Defective Green Coffee Beans

Defective green coffee beans can originate from the farm, during harvesting, processing, transportation, or storage. The Specialty Coffee Association (SCA) has established standards to classify green coffee beans. Through these standards, the relationship between defects and coffee flavor can be assessed. This article provides an overview of common types of green coffee bean defects to help you build basic knowledge and skills for proper selection and classification.

Read more: What is Specialty Coffee?

What Are Defective Green Coffee Beans?

In the coffee industry, defective green coffee beans—commonly referred to as “Defects”—are those with physical flaws caused by various factors. “By identifying defective green coffee beans, producers and roasters can improve product quality and ensure a better tasting experience for consumers

SCA Coffee Defect Classification Standards

The SCA has established a detailed classification system for identifying and evaluating common coffee defects. These standards are important not only for industry professionals in assessing quality, but also for helping consumers understand the quality of the coffee they are purchasing.

According to SCA, defects like moldy beans, malformed beans, or sun-damaged beans are classified based on specific criteria such as shape, color, and other physical characteristics.

Common Defects Found in Green Coffee Beans

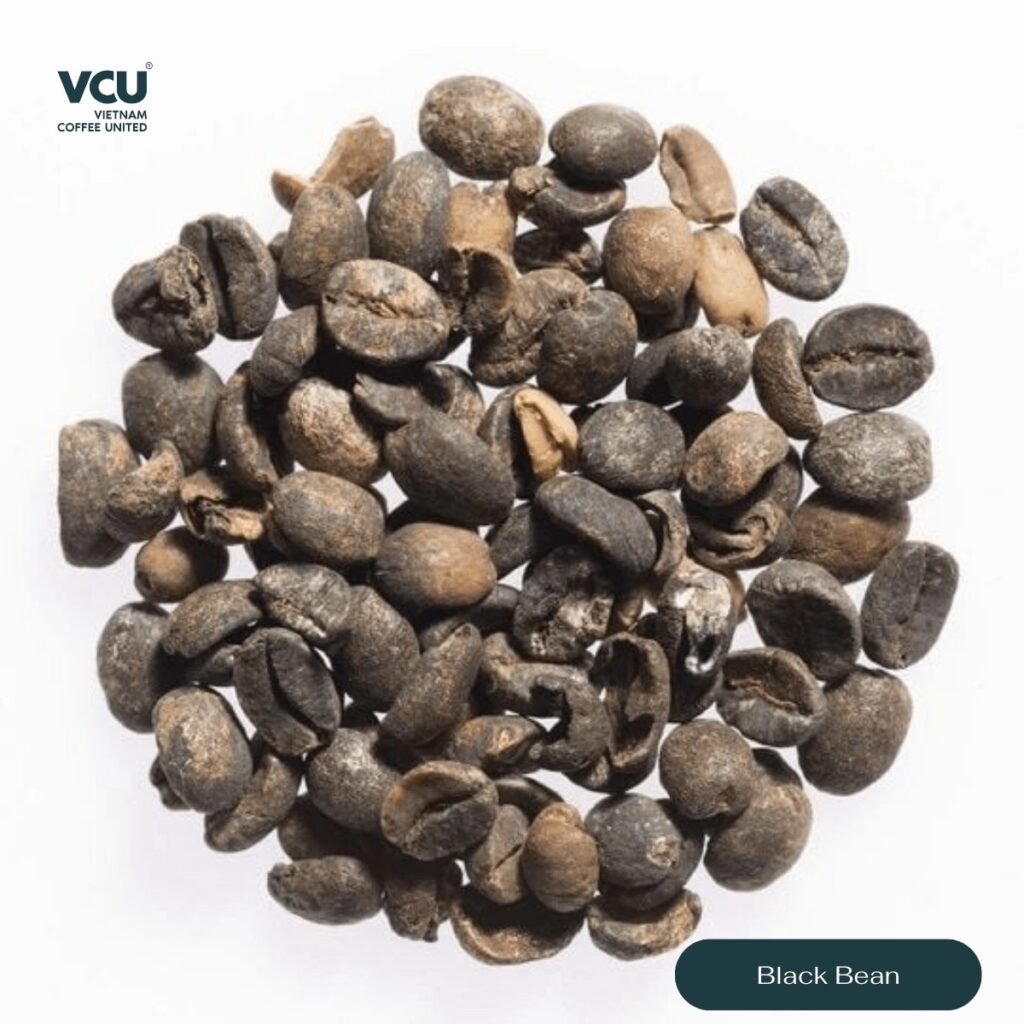

1. Black Beans

Also known as Black Beans, these defects result from overripe harvesting, over-fermentation during processing, or poor storage in humid conditions. Completely black beans are classified as primary defects, while partially black beans are secondary defects.

-

1 fully black bean = 1 primary defect

-

3 partially black beans = 1 secondary defect

When roasted, black beans can cause undesirable flavors such as dirty, moldy, or phenolic notes. Prevention includes harvesting at optimal ripeness and controlling fermentation time.

2. Sour Beans (Brown Beans)

These result from improper fermentation and are typically brown in color.

-

1 fully brown bean = 1 primary defect

-

3 partially brown beans = 1 secondary defect

To prevent sour beans, harvest only ripe cherries, avoid fallen fruits, and manage post-harvest storage and fermentation carefully. Timely and proper drying is also critical.

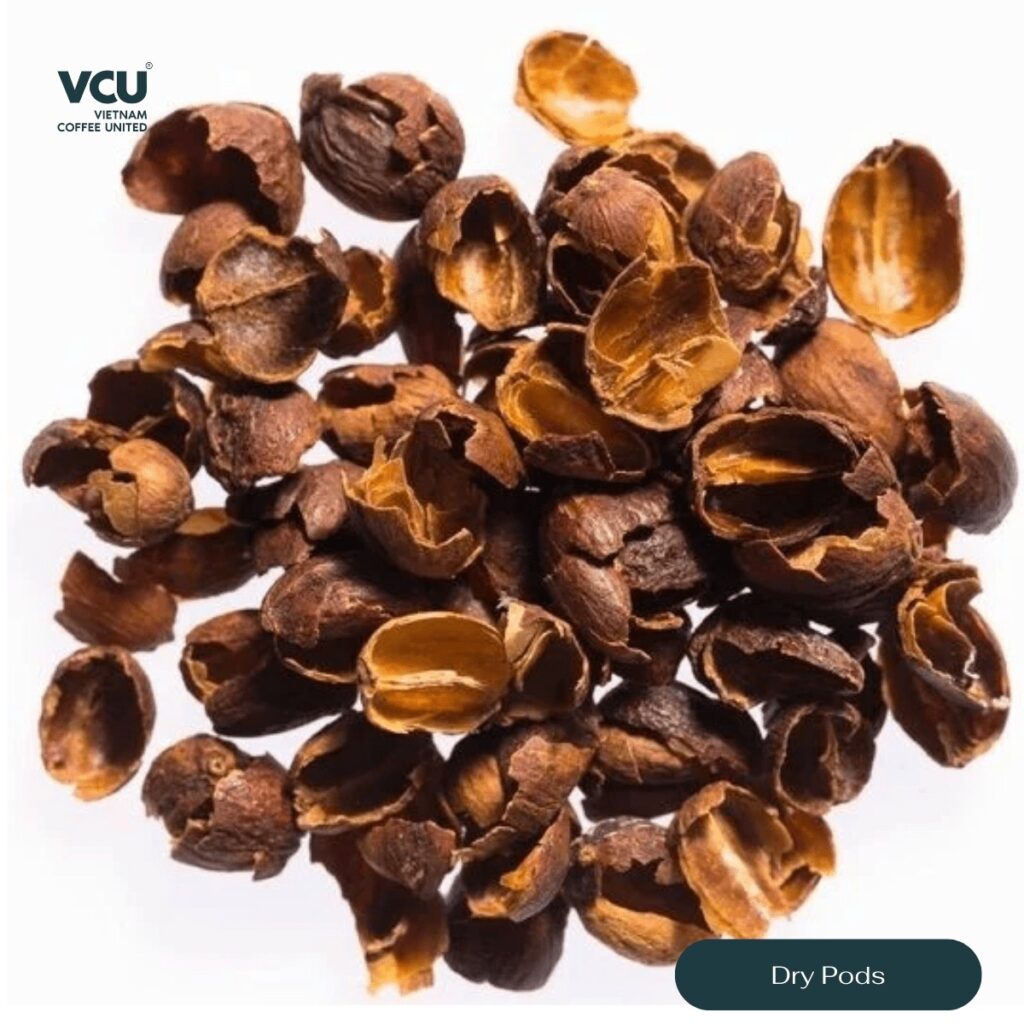

3. Dry Pods or Dried Cherries

In wet processing, “dry pods” occur when floaters (light, hollow beans) are not removed from the initial receiving tank. In natural processing, improper depulping and grading can also result in dry cherries.

-

1 dry cherry = 1 primary defect

These beans may contribute bitter, astringent flavors and harbor mold or bacteria. They also pose a fire risk during roasting.

4. Insect Damage

This defect is caused by pests such as the coffee berry borer.

-

5 heavily damaged beans (>3 holes) = 1 primary defect

-

10 lightly damaged beans (<3 holes) = 1 secondary defect

If not removed, these beans may result in sour, moldy, or burnt flavors after roasting.

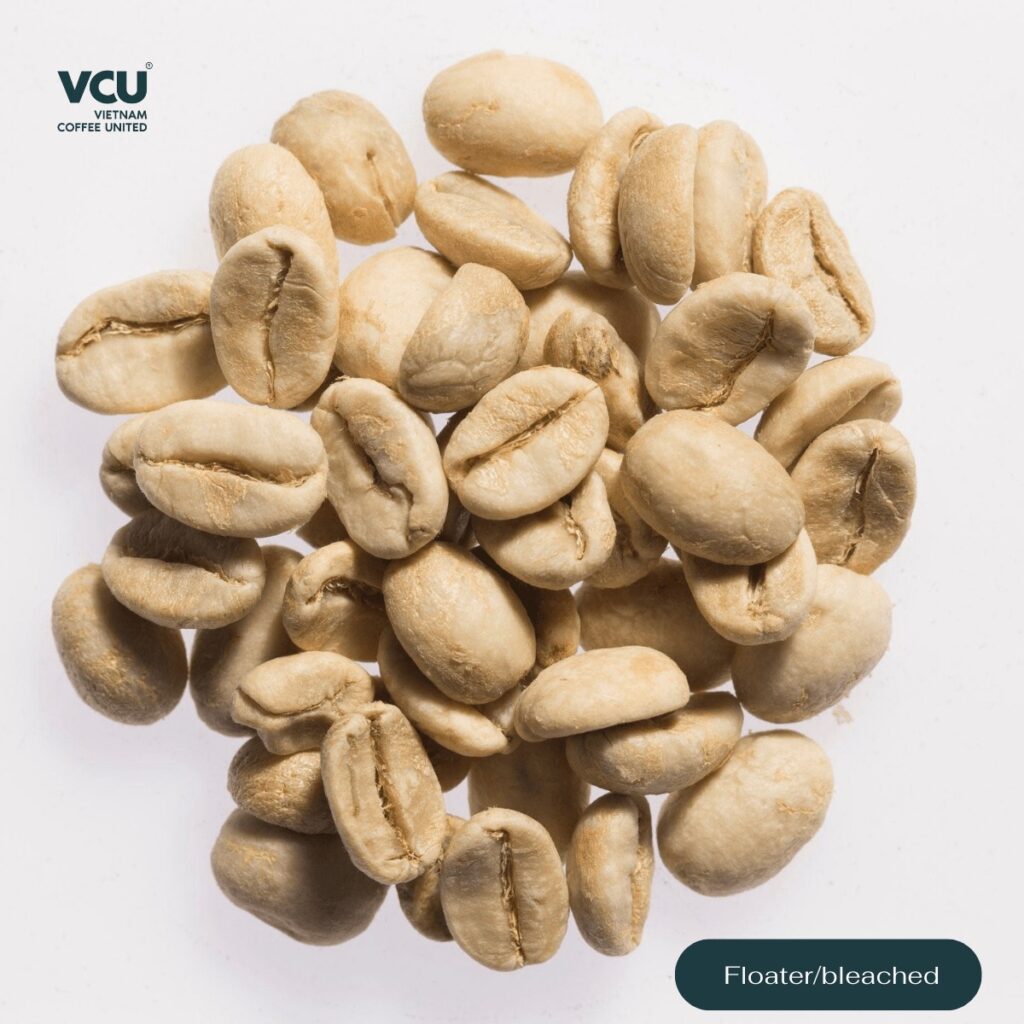

5. Floaters/Bleached Beans

Known as Floater or Bleached beans, these occur due to improper drying or long-term storage. They appear pale and light due to rapid drying.

-

5 floaters = 1 secondary defect

They often lead to undesirable flavors like fermented, grassy, earthy, or moldy notes.

6. Broken or Chipped Beans

Also called Broken or Chipped, these defects occur during hulling due to friction and mechanical damage.

-

5 broken beans = 1 secondary defect

Though they don’t severely impact flavor, they may produce earthy, sour, or fermented notes. Equipment calibration and screening are key to minimizing this issue.

7. Shell (Elephant Ear) Beans

Shell beans are malformed beans with separated internal and external parts.

-

5 shell beans = 1 secondary defect

While they don’t greatly affect flavor, they roast unevenly and can burn easily, causing burnt notes.

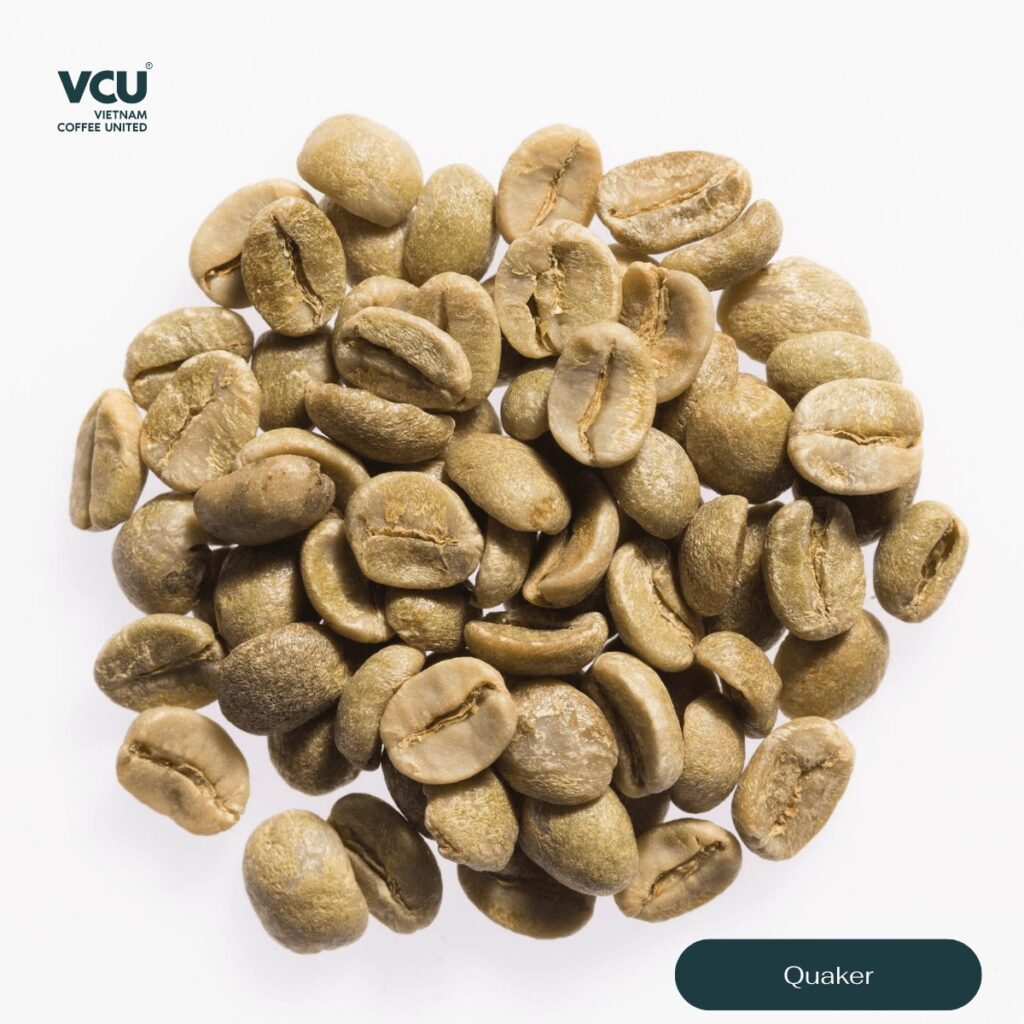

8. Quakers (Underripe Beans)

Quakers are unripe or underdeveloped beans. They are small, pale green, and lack the amino acids and sugars needed for Maillard reactions during roasting.

This results in flat, bitter flavors.

9. Moldy Beans

Fungus-damaged beans may be infected with Aspergillus, Penicillium, or Fusarium. These fungi thrive in humid conditions from harvest through storage. Moldy beans display powdery yellow to reddish-brown spots and may contaminate nearby beans.

10. Withered Beans

These occur when coffee cherries shrivel due to drought. Withered beans can produce grassy, hay-like flavors. In wet processing, they can be removed through flotation techniques; in dry processing, they are sorted by density and weight.

Before roasting, it’s essential to remove foreign matter like fruit skins, wood chips, stones, twigs, and other organic debris to protect equipment and ensure flavor quality.

In coffee processing and roasting, identifying green coffee defects is crucial. Understanding and addressing these issues allows producers, roasters, and consumers to enhance the overall quality and enjoyment of coffee.

Source: Compiled Information

Contact Information

VCU Joint Stock Company (VCU JSC)

Address:

– Roasting Facility: Residential Group 6, Chu Prong Town, Chu Prong District, Gia Lai Province

– Green Bean Facility: Ia Der Commune, Ia Grai District, Gia Lai Province

– Fanpage: VCU – Vietnam Coffee United

– Email: info@vietnamcoffeeunited.com