Honey Processing Coffee– A Unique Coffee Processing Technique Về Honey processing method is an innovative hybrid technique combining elements of both dry và wet processing to produce coffee beans with a distinctive honey-yellow color. While this method is widely recognized within the coffee industry, it does not have a single standardized name. In different regions, it may be known by various terms: the commercial names “Semi-Dry Process,” “Semi-Washed,” or “Hybrid Process” are often used. Each region where this technique is employed has its own unique name, reflecting the diversity of its application. For example, in Brazil (the birthplace of the technique), it is referred to as Pulped Natural. In Indonesia, it is called Giling Basah, which translates to “wet grinding” in Indonesian, and in Costa Rica, the method is locally known as Miel.

Expert Insight: The naming differences highlight the adaptability of the method across various coffee-growing regions. The diversity in terminology underscores how different cultures and farming practices have shaped the evolution of coffee processing.

Honey Processing at Las Lajas Micromill, Costa Rica: A Model of Sustainability and Quality One notable example of honey processing in action can be found at Las Lajas Micromill in Costa Rica. This micromill has gained international recognition for its commitment to high-quality, sustainably produced coffee. The farm utilizes the honey process to enhance the flavor profile of its coffee beans, contributing to the distinctive miel (honey) flavor that Costa Rican coffee is famous for. The careful control of fermentation and drying stages at Las Lajas allows for the development of rich, nuanced flavors in the final cup, highlighting the farm’s dedication to both traditional and innovative coffee practices.

The Benefits of Honey Processing: Efficiency and Flavor Enhancement Về primary advantage of honey processing over dry processing lies in the enhanced efficiency of the drying process and the improved flavor characteristics achieved through controlled fermentation. This method provides a more consistent drying environment, reducing the risk of spoilage and allowing for greater control over the final flavor profile. According to Cafeimports, the fermentation process in honey processing is more controlled and less prone to the risks often associated with wet processing, such as over-fermentation or the growth of undesirable bacteria. This makes honey processing a valuable alternative for coffee producers seeking to maintain both quality and consistency in their beans.

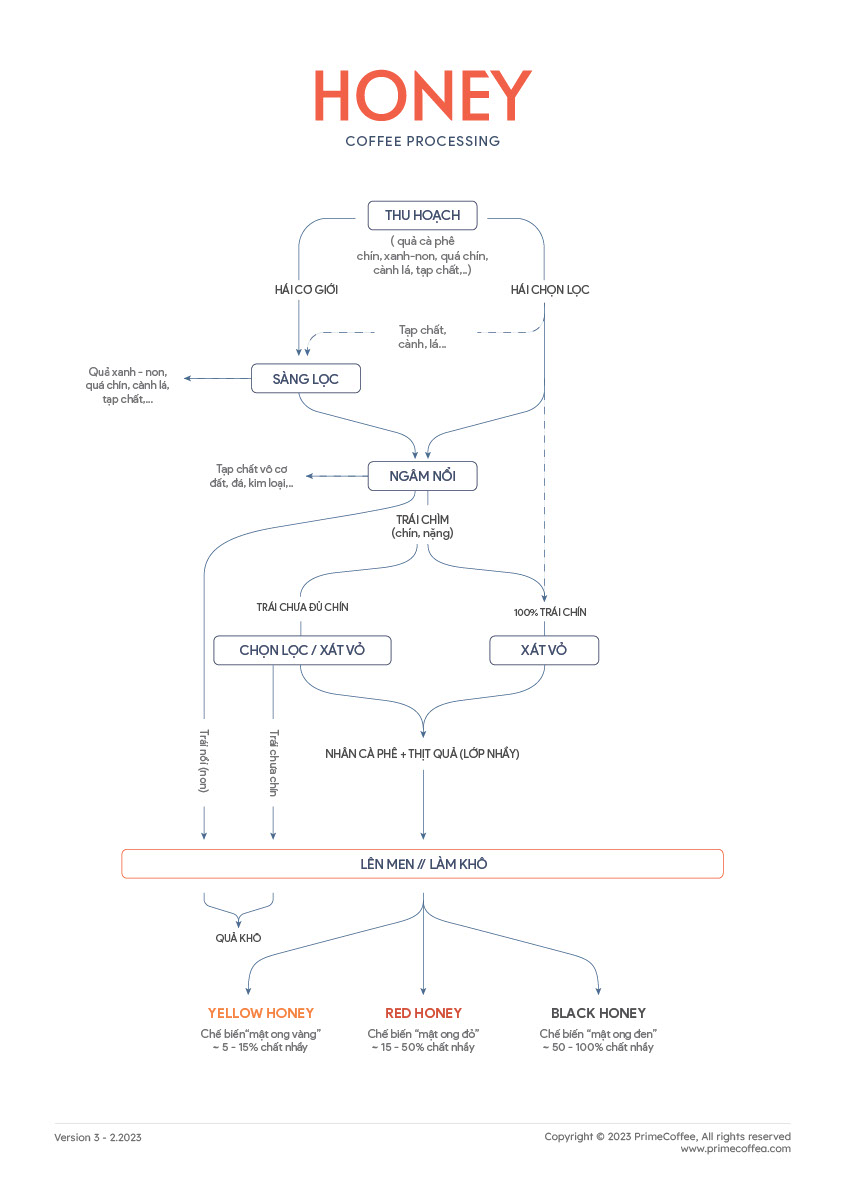

Honey processing techniques

Understanding Coffee Processing Techniques: Natural, Washed, and Honey When it comes to coffee processing, there are three primary methods: Natural, Washed, and Honey. Each method affects the final flavor profile and quality of the coffee in distinct ways.

- Natural Coffee: This method involves drying the coffee cherries before removing the hull and grinding the beans. This results in a coffee with a fruity, full-bodied flavor, as the beans retain much of the natural sugars and flavors from the fruit.

- Washed Coffee: In this process, the coffee cherries are hulled and fermented, which helps break down the pulp (also known as mucilage) before drying. This method typically produces a cleaner, more acidic cup of coffee.

- Sơ chế honey: The Honey processing method bridges the gap between washed và natural methods. After the cherries are hulled, the coffee is dried with the mucilage still attached to the beans. This allows for the retention of some of the sweetness and complexity found in natural coffee, while also benefiting from the fermentation process seen in washed coffee.

Expert Insight: Honey processing allows for a more balanced cup, offering a harmonious blend of sweetness, acidity, and body that is increasingly sought after in specialty coffee circles.

Honey Processing vs. Wet Processing: A Simplified Method While honey processing may seem like a hybrid method (combining both wet and dry processing techniques), it is, in fact, a simplified version of wet processing. In traditional wet processing, after the coffee cherries are peeled, the beans are soaked in a fermentation tank for 24 to 36 hours, allowing the mucilage to break down. In contrast, honey processing involves minimal fermentation — typically lasting no more than 12 hours — to retain some of the mucilage (the sticky fruit flesh) around the bean. After fermentation, the beans are moved to the drying stage, where they are dried until the moisture content reaches between 10% to 12%.

Expert Insight: By reducing the fermentation time, honey processing minimizes the risk of undesirable flavors and allows coffee producers to better control the drying process.

Honey Processing / Semi-Wet (Printable poster available at PrimeCoffee )

Why Is It Called Honey Processing? The term “honey processed” may confuse some coffee drinkers into thinking that honey is used in the brewing process or that the coffee itself has a honey-like flavor. However, the name actually refers to the sticky texture of the coffee bean before it is dried. After the coffee cherries are removed, the beans are coated in a slimy mucilage that gives the beans a sticky, honey-like feel. As the beans dry, the mucilage continues to absorb moisture from the air, increasing the stickiness, which is why the method is called honey processing.

Distinguishing Honey Processing from Wet Processing

One of the key differences between honey processing và wet processing is that honey processing involves fermentation without water. The mucilage, which is composed of water, sugars (carbohydrates), and organic substances like pectin and proteins, is naturally sticky and can be difficult to remove mechanically. However, this mucilage is highly susceptible to microbial activity, meaning that it will naturally decompose due to the action of enzymes secreted by microorganisms (and also by enzymes

Coffee Hulling in Indonesia: A Key Step in the Coffee Processing Journey In Indonesia, coffee hulling is an essential step in preparing the coffee beans for export. After the coffee cherries are harvested, they undergo a series of processes that remove the outer layers of the fruit. Hulling involves removing the parchment layer that surrounds the coffee bean. This process is crucial to ensure that only the high-quality beans are selected and prepared for roasting. It’s important to note that Indonesia is known for its diverse coffee-growing regions, and each region may have unique methods for hulling and processing coffee, which contribute to the distinct flavor profiles of Indonesian coffee. The wet hulling method, for example, is particularly popular in Sumatra, giving coffee beans a rich, earthy flavor.

Expert Insight: Indonesia’s coffee industry has developed a reputation for its high-quality Arabica and Robusta beans. The hulling process is key in maintaining the quality of these beans, which are renowned for their bold and distinctive flavors.

Coffee hulling in Indonesia

Environmental Benefits of Honey Processing: Water Conservation and Waste Reduction One of the primary environmental benefits of honey processing is that it consumes significantly less water compared to traditional wet processing. Wet processing requires large amounts of water for fermentation and washing, which can result in substantial wastewater that may be difficult to treat, especially in coffee-growing regions where water resources are scarce. In contrast, honey processing uses minimal water during fermentation, making it an ideal method for water-constrained areas. This approach not only reduces water usage but also minimizes waste, making it a more sustainable option for coffee farmers. Additionally, honey processing allows the coffee to undergo fermentation without requiring high mechanization, contributing to its environmental benefits. As a result, this method is sometimes referred to as a Hybrid Process, as it offers a balance of quality and sustainability.

Expert Insight: Honey processing offers an important solution to the environmental challenges faced by the coffee industry, particularly in areas where water resources are limited or expensive. By minimizing water use and reducing wastewater, honey processing can be a more eco-friendly alternative to traditional wet methods.

The Origins and Evolution of Honey Processing

The Origins and Evolution of Honey Processing The concept of honey processing was first pioneered in Brazil by the Agronomic Institute of Campinas (IAC) in the early 1950s. However, it wasn’t until the 1980s that the technique began to gain widespread use in coffee farms, particularly in the southern region of Minas Gerais. During this time, a few farmers began to experiment with semi-wet processing on a commercial scale, discovering that it resulted in positive improvements in coffee flavor and quality.

The adoption of this processing method took off in the 1990s when Pinhalense, a renowned equipment manufacturer, developed specialized milling machines for honey processing. This innovation helped to scale the method, and Pinhalense’s machines were introduced in various coffee-growing regions, both in Brazil and abroad. These developments were pivotal in the commercialization of honey-processed coffee, which was first marketed under the name “Cereja Descascado” (or CD).

Originally,

‘Pulped Naturals’ originated in Brazil, it was only when it came to Costa Rica that it was called ‘Honey Proces’ (The Craft and Science of Coffee)

As the technique continued to evolve, it spread to other countries, particularly Costa Rica, where it was rebranded as “Miel” (honey). Today, honey processing is celebrated globally as a way to produce coffee with a rich, complex flavor profile that showcases the unique characteristics of the beans.

Expert Insight: Brazil’s role in pioneering honey processing has had a profound impact on the global coffee industry, particularly in terms of quality và innovation. The country’s adoption of this method helped establish honey processing as a mainstream technique used by specialty coffee roasters worldwide.

Honey processed coffee yellow, red & black

Honey Processed Coffee: Yellow, Red, and Black Variants When discussing honey processed coffee, you’ll often encounter color descriptors such as yellow, red, and black honey. These terms refer to the level of mucilage retained during the drying process, rather than any flavor characteristics related to honey itself.

Honey processed coffee: yellow, red, black; dry and wet processed

The term “honey” in this context actually refers to the sticky texture of the coffee beans during processing, not the flavor of the brewed coffee. The fruit flesh surrounding the bean does not fully decompose during fermentation, leaving behind some sugars and enzymes that contribute to the sticky layer.

- Yellow Honey: When about 25% of the mucilage remains, the beans are dried quickly (typically in 8-10 days), resulting in a yellow hue. The flavor profile is similar to that of wet-processed coffee, with a bright acidity.

- Red Honey: This variety retains 50-75% of the mucilage and is dried more slowly, taking around 12-15 days. The slower drying process enhances the bean’s complexity and sweetness, resulting in a fuller, richer flavor.

- Black Honey: Nearly 100% of the mucilage remains, and the drying process takes up to 30 days. This variant is the most labor-intensive to produce, requiring frequent turning of the beans to prevent clumping. Black honey beans tend to develop the deepest, most complex flavors, with earthy and fruity notes.

Expert Insight: The color of honey-processed coffee is a direct result of the mucilage retention and drying time. Understanding these color variations allows coffee professionals and enthusiasts to better anticipate the flavor profile and quality of the beans.

Villa Sarchi coffee is processed with black honey at Hacienda Tobosi in Costa Rica

Amplifying Specialty Coffee Flavors with Honey Processing By applying semi-wet processing (honey processing) to specialty coffee varieties such as Geisha, Bourbon, Catuaí, Typica, and Maragogype, coffee producers can significantly enhance the intensity và complexity of the coffee’s flavor profile. Honey-processed coffees are often highly sought after in specialty coffee competitions, such as the Cup of Excellence, Specialty Coffee Association events, and Best of Panama, where they frequently score among the highest.

However, honey processing requires careful monitoring during the drying phase. Due to the high moisture content of the mucilage, the beans are particularly susceptible to mold growth, which can cause spoilage and undesirable flavors if not carefully managed. Coffee beans must be regularly turned during the drying process to ensure uniform moisture evaporation and to prevent mold formation, especially in humid climates.

Expert Insight: While honey processing can significantly enhance the flavor profile of specialty coffee, it demands attention to detail during every stage of processing, particularly in maintaining proper drying conditions.